Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

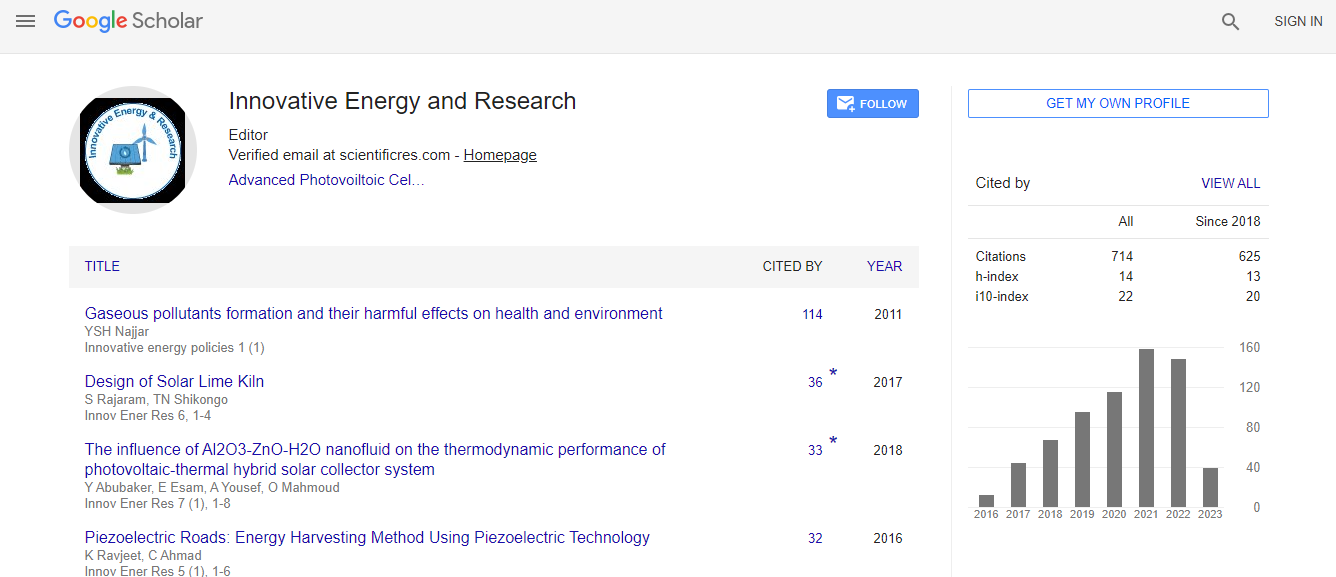

Google Scholar citation report

Citations : 712

Innovative Energy & Research received 712 citations as per Google Scholar report

Innovative Energy & Research peer review process verified at publons

Indexed In

- Google Scholar

- Open J Gate

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Online structural health monitoring of composites using screen printed nano-composite sensors

20th International Conference on Advanced Energy Materials and Research

Taimoor A Khan, Saad Nauman and Zaffar M Khan

Institute of Space Technology, Pakistan

Posters & Accepted Abstracts: Innov Ener Res

Abstract

This research aims to develop CNPs based piezoresistive sensor through screen printing and correlate the strain rate to predict the failure response of glass fibre composites. This involves homogenous dispersal of carbon nano- particles (CNPs) in polystyrene (PS) resin through sonication. The smart sensing layer is deposited on glass fibre reinforced composite structures for sensing. The concentration of CNPs was maintained at the percolation threshold of 35% by weight which ensured higher sensitivities and damage detection capability. The composite notched specimens were tested in tension according to ASTM standard to validate the sensing characteristics of the smart layer. It was found that the screen printed smart sensing layers were capable of monitoring strains like traditional strain gauges but with higher gauge factors of 20. The screen printing techniques, due to its low cost and easy implementation, is recommended as a reliable method of sensor integration on various types of substrates including plastics & composites.Biography

E-mail: taimoor.khan95@gmail.com

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi