Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

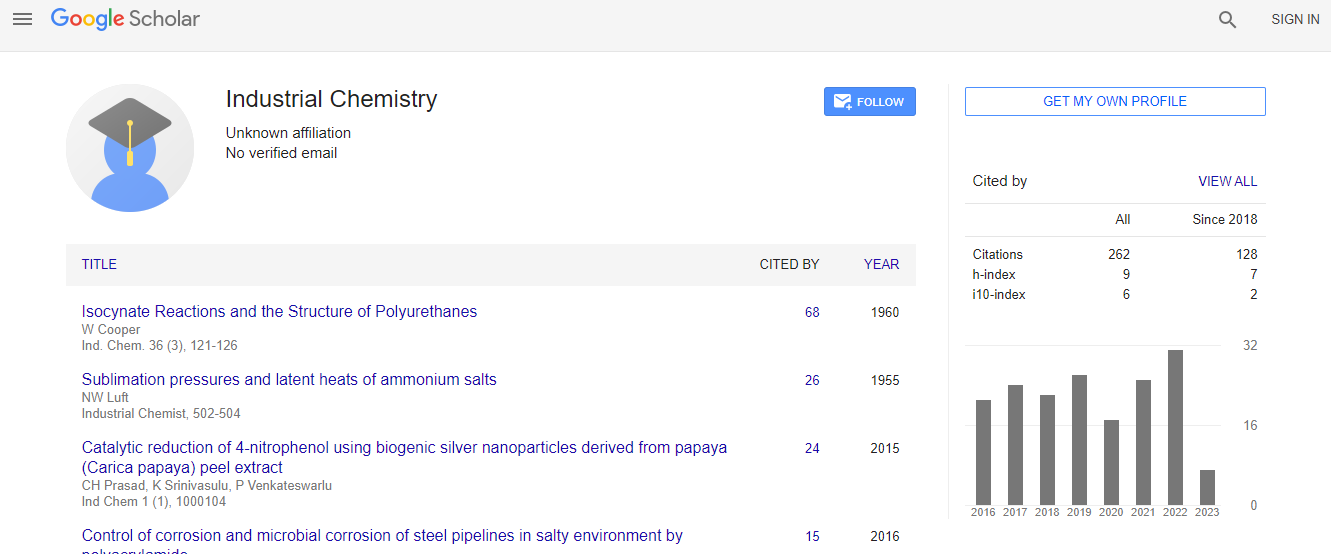

Google Scholar citation report

Citations : 262

Industrial Chemistry received 262 citations as per Google Scholar report

Indexed In

- Index Copernicus

- Google Scholar

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Geneva Foundation for Medical Education and Research

- Euro Pub

Useful Links

Recommended Journals

Related Subjects

Share This Page

Evaluation of monomeric sugar yield from various grasses grown in Thailand as biofuel feedstock by two-stage pretreatment process

International Conference on Industrial Chemistry

Sujitra Wongkasemjit

Chulalongkorn University, Thailand

Keynote: Ind Chem

Abstract

Napier grass (Pennisetum purpureum), Tiger grass (Thysanolaena maxima), Mission grass (Pennisetum polystachyon), Kans grass (Saccharum spontaneum) and Giant reed (Arundo donax) were locally collected to test as bioethanol feedstock. All grasses, showing high cellulose and hemicellulose compositions, were treated by a two-stage microwave/ chemical pretreatment method. The optimum conditions of the pretreatment were investigated and the maximum monomeric sugar yields were compared. The microwave-assisted NaOH and H2SO4 with 15:1 liquid to solid ratio were studied by varying catalyst concentration, temperature, and time to maximize the amount of the obtained monomeric sugar. The maximum monomeric sugars released from microwave-assisted NaOH pretreatment were 5.57 g (at 600C/10 min, 0.5%(w/v) NaOH for Napier grass), 6.45 g (at 1400C/15 min, 1%(w/v) NaOH for Tiger grass), 6.56 g (at 1200C/10 min, 3% (w/v) NaOH for Mission grass), 6.78 g (at 800C/5 min, 5% (w/v) NaOH for Kans grass), and 6.84 g (at 1200C/5 min, 5% (w/v) NaOH for Giant reed) per 100 g biomass, while maximum monomeric sugars from microwaveassisted H2SO4 pretreatment were 42.03 g (at 1600C/15 min, 1% (w/v) H2SO4 for Napier grass), 30.37 g (at 2000C/5 min, 0.5% (w/v) H2SO4 for Tiger grass), 34.34 g (at 2000C/5 min, 1%(w/v) H2SO4 for Mission grass), 33.76 g (at 2000C/10 min, 0.5% (w/v) H2SO4 for Kans grass), and 31.91 g (at 1800C/30 min, 0.5% (w/v) H2SO4 for Giant reed) per 100 g biomass.Biography

Sujitra Wongkasemjit has completed her PhD from West Virginia University and Post-doctoral studies from Food and Drug Administration, USA. She is a Professor of Petroleum and Petrochemical College, Chulalongkorn University. She has published more than 100 papers in reputed journals, 7 local patents, 2/3 books/book chapters, and more than 200 international presentations.

Email: dsujitra@chula.ac.th

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi