Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

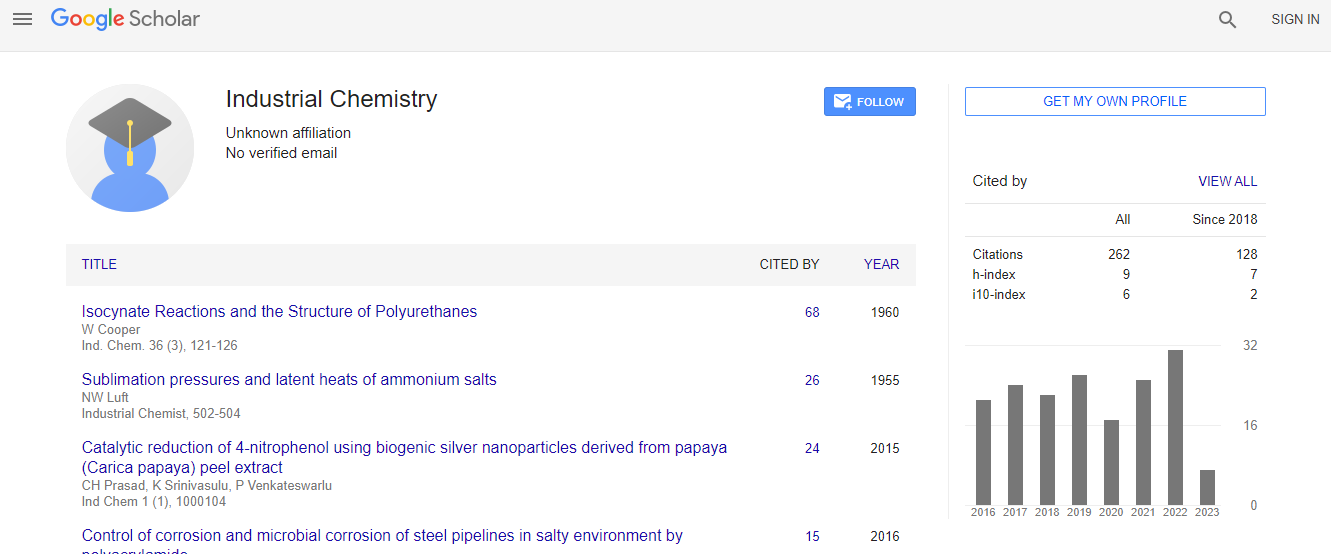

Google Scholar citation report

Citations : 262

Industrial Chemistry received 262 citations as per Google Scholar report

Indexed In

- Index Copernicus

- Google Scholar

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Geneva Foundation for Medical Education and Research

- Euro Pub

Useful Links

Recommended Journals

Related Subjects

Share This Page

Stiffening mechanisms in vermiculite-amorphous polyamide bio-nanocomposites

International Conference on Industrial Chemistry

Afonso D Macheca, Walter W Focke, Herminio F Muiambo and Mustapha Kaci

University of Pretoria, South Africa

Posters & Accepted Abstracts: Ind Chem

Abstract

Sub-micron thick flakes were obtained by sonication of vermiculite that was first exfoliated by either thermal shock or chemical treatment with hydrogen peroxide. Dimer fatty acid polyamide nanocomposites with a mixed morphology were prepared via a solution-dispersion technique. The large (in the micrometre range) vermiculite flakes assumed random orientations in the matrix. BET surface area measurements indicated flake thickness below 100 nm but SEM showed that thicker flakes were also present. Filler content was varied up to 30 wt.%. At this loading, the tensile strength doubled, the modulus increased five-fold but the elongation-at-break decreased by a factor of ten. Dynamic mechanical analysis suggests three stiffening mechanisms. The reinforcing effect of the high stiffness inorganic flakes is the primary contributor. Together with the chain confinement effect, that expresses itself in an apparent increase in the glass transition temperature, provides an adequate rationalisation of the stiffness variation below Tg. However, an additional stiffening effect is indicated at temperatures above Tg. The mechanism may involve dynamic network formation based on fluctuating hydrogen bonding interactions between the matrix polymer chains and the filler particles.Biography

Email: afonso.macheca@uem.mz

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi